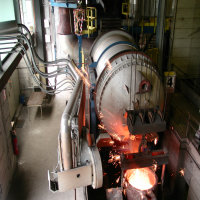

ROTARY OXY-COMBUSTION MELTING FURNACE FOR CAST IRON

The technology to melt cast iron without pollution and with low requirement of power

Sogemi has over 20 years of experience in the construction of cast iron melting rotary furnaces with oxy-combustion, developed with the aim of reducing running costs and in order to improve environmental impact, thereby reducing the levels of pollution arising from the melting process with a cupola furnace.

Sogemi, with the collaboration of the main oxygen suppliers, has developed a technology that plays a leading role in the foundry.

Sogemi has so far been responsible for the installation of over 150 plants worldwide, which cover all possible applications, from the smaller sized furnaces to the larger furnaces for mass production.

Sogemi furnaces distinguish themselves by virtue of the following:

- Excellent heat transfer: flame at 2800°C, with a high degree of radiation and thermal exchange by the refractory material for conveyance thanks to the rotary motion.

- Controlled melting in oxidizing or reducing environments, with rapid temperature increase (over 6°C a minute)

- Tapping temperature up to ~ 1550°C

- Rapid automatic loading and slag removal thanks to the possibility of tilting the furnace until it is in vertical position.

Furnace for large sized castings

It's the ideal solution for those producing large sized castings: in fact the rotary furnace ensures the availability of molten metal in short time, rapid pouring into the ladle.

Furnace for automatic moulding lines

In this second application the rotary furnace is connected with a electrical holding furnace, from which it takes the iron to pour into the molds/flasks of the automatic moulding line.

-

High quality metallurgy:

- Grey iron and nodular/ductile iron. As well as iron alloys (Ni Hard, Ni Resist, Ferritic).

-

Environment friendly:

- Reduced dust emission (no coke);

- Incredible reduction in fume volumes (no air);

- Minimum S02 content in the fumes (no coke);

- Reduction in N0x emission levels (no air);

- Cleaner foundry working environment.

-

Competitive costing:

- Low initial investment requirement: simple technology;

- Low running costs: no electricity;

- Reduced labour requirements: a single operator for two furnaces.

-

Process flexibility:

- PLC controlled system to ensure complete reproductive capacity;

- Excellent repetitive potential of the chemical analysis of the metal;

- Possibility of load alteration: production flexibility;

- Melting and holding: in the same furnace.

-

Minimum maintenance:

- Mechanical and electrical maintenance: minimal;

- Refractory material: one hour each week together with a small quantity of repair material; complete reparation once a year.

-

Wide range of solutions:

- Furnace capacity between 2 and 30 ton

Operational cycle

| Rotary furnace capacity | 3 tons | 5 tons | 10 tons | 15 tons | 20 tons | 30 tons |

|---|---|---|---|---|---|---|

| Preliminary operations | 15 min | 15 min | 15 min | 15 min | 15 min | 15 min |

| Loading | 10 min | 10 min | 12 min | 15 min | 20 min | 25 min |

| Melting time with ALJET cycle | 60 min | 75 min | 90 min | 110 min | 120 min | 135 min |

| Cast iron tapping | 10 min | 10 min | 10 min | 10 min | 15 min | 20 min |

| Slagging | 5 min | 5 min | 5 min | 10 min | 10 min | 15 min |

| Total cycle time | 100 min | 115 min | 132 min | 160 min | 180 min | 210 min |

| Cast iron production | 1,8 t/hour | 2,61 t/hour | 3,64 t/hour | 5,62 t/hour | 6,67 t/hour | 8,57 t/hour |

Consumption: Oxygen plus Methane or Propane or Gas Oil

| Furnace | Melting Time (min) | Gas Oil (kg/t) | Methane (Nm3/t) | Propane (Nm3/t) | Oxygen (Nm3/t) | Temperature (°C) |

|---|---|---|---|---|---|---|

| 3 ton | 60 | 34-39 | 39-44 | 15-17 | 130-150 | 1450 |

| 5 ton | 75 | 34-39 | 39-44 | 15-17 | 130-150 | 1450 |

| 10 ton | 90 | 34-39 | 39-44 | 15-17 | 130-150 | 1450 |

| 15 ton | 110 | 32-37 | 37-42 | 14-16 | 125-140 | 1450 |

| 20 ton | 120 | 32-37 | 37-42 | 14-16 | 125-140 | 1450 |

| 30 ton | 135 | 32-37 | 37-42 | 14-16 | 125-140 | 1450 |

PCI methane: 10 kWh/Nm3; PCI propane: 25.4 kWh/Nm3; PCI gas oil: 11.6 kWh/kg, with ρ = 0.89-0.93 kg/l at 15°C.